charpy impact test brass alloy|charpy impact test temperature : distributors In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disa. Resultado da PortalPed é um site que compartilha conhecimento em Pediatria, com publicações sobre saúde, nutrição, vacinas, doenças e cuidados com .

{plog:ftitle_list}

webAs origens da Casa dos Contos remontam ao final do final do século XIII, tendo sido extinta e substituída pelo Erário Régio em 22 de Dezembro de 1761, por alvará da autoria de .

The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction .The Charpy impact specimens of each material are immersed in a bath for 10 minutes to reach thermal equilibrium at five separate temperatures ranging from -110 o F (-79 o C) to 212 o F .

In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disa.Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This .

Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to measure a material’s notch toughness at moderately high strain rates. It is defined by the ASTMThe Charpy V-notch impact is a mechanical test for determining qualitative results for material properties and performance which are useful in engineering design, analysis of structures, and .

The Charpy impact test, also commonly referred to as the Charpy V-notch test by material scientists, serves as a standardized high-strain rate examination to quantify the energy absorbed by a material upon fracture. The .

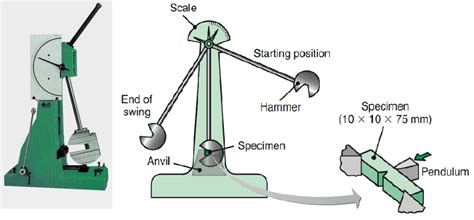

A Charpy test determines the impact toughness of metal samples by striking them with a swinging mass. The traditional test method requires measuring the difference between the height of the striker before and after impact. The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is . The impact property is one of the most significant mechanical properties for metallic materials. In the current work, a soft–hard copper–brass block with a high yield strength of ~320 MPa and good uniform elongation of .

The ultimate tensile strength, yield strength, elongation and reduction of area were obtained from the average of three repeated testing results. Impact toughness was tested on an impact tester at room temperature, using standard Charpy V-notch impact samples with a size of 10 mm × 10 mm × 55 mm. Impact toughness presented in this study was .

According to the Charpy impact test results, the third sample having 1000 °C casting temperature had higher breaking energy compared to samples casted at 1200 °C and 1100 °C. Aluminum alloy wheels are used worldwide in both the warmest and coldest temperatures. This study was conducted to investigate the impact resistance of aluminum alloy wheels produced by the low-pressure die casting process in real-life conditions. The V-notched Charpy impact test specimens were extracted from T6 heat-treated A356 aluminum alloy . The tensile and Charpy impact properties of Ti5111 alloy under different temperatures: (a) engineering stress-strain curves, (b) the variations of R p0.2 and EL on the test temperature, (c) the impact load-deflection curves, and (d) the variation of impact absorbed energy on the test temperature.The Charpy impact test has been used for the toughness assessment of metallic materials for one hundred years. It is standardized and largely applied in industry, due to the simple, rapid and inexpensive testing procedure. Charpy impact testing is largely employed for characteriz-ing a material’s DBTT (ductile-to-brittle transition temperature).

The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the requirements for specimens, for the performance of the test, for result reports and for testing machines, i.e., pendulum impact testers at ambient .

The Charpy Impact test is a high strain-rate method used to assess the impact toughness of metals and alloys. . Copper and its alloys, such as brass and bronze, may undergo impact testing to evaluate their suitability for various applications, including electrical components, plumbing fixtures, and architectural elements. Impact testing helps . Charpy impact testing (also known as the Charpy v-notch test) is a high strain rate testing standard that determines the amount of energy absorbed by a material during a fault (Kim et al., 2015). In this study, the brass alloys were produced by a sand casting method at different casting temperatures. Structural and mechanical properties were observed. Optical microscope, XRD and the SEM analysis were performed for the microstructure and phase analysis of the material. . Charpy impact test and tensile test were applied to consider the .

Impact testing, employing the standard Charpy V-Notch method and performed at ambient temperature, showed significantly higher toughness for the CuZn36Pb2As alloy (30 J) compared to the CuZn39Pb3 alloy (13 J), see Table 2 and Fig. 7.

The Charpy impact test results are collectively presented in Fig. 4. A marginal increase in impact energy of around 10% was observed in case of CW510L brass alloy (from 47 J to 52 J). Conversely, in case of CW511L brass alloy a 20% reduction in impact energy was observed (from 104 J to 84 J).

Longitudinal orientation. The three toughness values for CarTech AerMet 100 alloy obviously vary considerably in magnitude. Compare the values mentioned for CVN impact energy and fracture toughness with the area under the stress-strain curve of 4291 (calculated as (16.1) x . Figure 8 — Charpy vs Impact test Fracture modes. . Finally, when comparing the brass and steel V type specimens, the brass one has a very low toughness compared to the other. And its facture .Figure 3 Schematic of impact testing The material used in this study is brass (Cu-Zn) with a chemical composition as shown in Table 1. Referring to . [16], the Charpy impact value of the brass alloy is 15 - 69 Joule. However, the Charpy impact value depends on the chemical composition and treat-ment of the metal alloy. The results in this .

Charpy Impact Testing. Charpy impact tests are routinely undertaken during the production of metals. ASTM A370 is the most used standard for measuring the toughness of metal samples. Testing is typically undertaken at room .According to current Charpy test standards (ASTM E23-12c and ISO 148-1:2009), absorbed energy (KV) results from partially fractured test specimens can be averaged with the results from fully fractured specimens. However, most researchers agree that if a specimen does not fully fracture at the end of a Charpy test, a significantIn this paper the influence of notch acuity and test temperature on the impact behavior of aluminum alloy 6061 is presented and discussed. Notch angles of 45°, 60°, 75° and 90° were chosen for a standard charpy impact test specimen containing two such notches positioned at right angles to the applied load. For a given angle of the notch the dynamic fracture toughness .

The Charpy impact test, also commonly referred to as the Charpy V-notch test by material scientists, serves as a standardized high-strain rate examination to quantify the energy absorbed by a material upon fracture. The absorbed energy functions as an indicator of the material’s notch toughness. Materials. Three lead-free brass rods (CW510L-CW511L-C27450) and a leaded brass rod (CW614N) with a 35 mm nominal diameter (after hot extrusion and light cold drawing (Ref 1)) were employed for this study.The composition of the alloys as determined by optical emission spectrometry (OES) is shown in Table 1.Brass alloys are in compliance with the EN .impact testing of mild steel, the Charpy Impact Test can provide information on how much energy a specimen such as mild steel can absorb under an impact scenario. In this context, the following sections will present information on: 1) impact testing; 2) effect of .

undersized charpy impact test

An Instron testing machine was used with a crosshead speed of 0.02 in. per min. Test procedures are described by R.A. Warren and R.P. Reed in NBS Monograph 63. Results — The figures on the following pages present stress-strain behavior. In Table 2 the average data for each alloy are tabulated for all tests and temperatures.

42 ENGINEERING 36 MATERIALS SCIENCE CHARPY TEST COMPARATIVE EVALUATIONS STEEL-CR2MOV IMPACT TESTS ENERGY ABSORPTION SHEAR PROPERTIES STEEL-ASTM-A533-B WELDED JOINTS Charpy impact testing verification 2-mm striker 8-mm striker lateral expansion instrumented striker energy percent shear standard . A Charpy test determines the impact toughness of metal samples by striking them with a swinging mass. The traditional test method requires measuring the difference between the height of the striker before and after impact. An instrumented striker, on the other hand, has force .The Charpy impact test is performed to evaluate the resistance of the metal to breakage by flexural shock or impact load according to standard test method ASTM D6110. Fig 1: Charpy Test Apparatus. This test determines the amount of energy absorbed by a material during fracture. This absorbed energy is a measure of a given material’s notch .

cobalt-based alloys; copper-based alloys-brass-bronze iron based alloys; aluminum-based alloys; titanium-based alloys; MACHINE SHOP DEPARTMENT . Machine Flattening Rings Machine & Surface Grind Macro Specimens PHYSICAL TESTING DEPARTMENT; Welder Certification Charpy Impact Testing Welding Procedures Hardness Testing Tensile Testing .

Test criteria for Charpy V-notch impact testing usually involve (i) a minimum impact energy value, (ii) shear appearance of fractured test bars expressed in percent, and (iii) lateral expansion. For steels, the minimum acceptable values generally specified for these three evaluation methods are 20 J, 50 % shear, and 1.3 mm respectively.

is the prometric cna test hard

is the property and casualty insurance test hard

web30 de jan. de 2024 · ArticlesCellular And you may Tablet PlayingMention The fresh Makers Of good Ports GamesJust what Casino games Should i Utilize them for?Rating fifty Free Spins For the Very first Put + Extra 30 100 percent free Revolves! All of us will make sure they keep appropriate permits relevant so you can United states Gaming regulations. We're

charpy impact test brass alloy|charpy impact test temperature